The U.S. government declared a state of emergency in 17 states and Washington, D.C. on the 9th. The reason is that the largest fuel transmission pipeline in the United States was forced to shut down due to a cyber attack, which affected 45% of the supply of gasoline, diesel and other fuels on the east coast of the United States, and the specific recovery time is still far away.

This incident has made the international community attach great importance to the safety of oil pipelines, and the construction of smart pipe corridors has once again been put under the spotlight. In recent years, with the rise of network automation attacks, old infrastructure and systems are easily attacked. Infrastructure and systems such as oil pipelines are in urgent need of upgrading, and the construction of smart pipe corridors cannot be delayed!

Smart pipe gallery is based on all kinds of intelligent monitoring equipment, data fusion analysis and application as means, combined with intelligent sensing, 3S (GIS, GPS, RS) and 3D modeling and other technologies, to achieve rapid access to various information of pipe gallery , Accurate and reliable collection and processing, and display and operation on a unified information management platform.

Building Ideas

Smart perception: Use advanced sensing and transmission technology to fully perceive the key information of the pipe gallery, give early warning to accidents that affect the normal operation of the pipe gallery, and implement advanced control.

Smart management: Use advanced technologies such as cloud computing, virtual reality and the Internet of Things to establish a unified intelligent supervision platform to realize intelligent management and improve operation and maintenance efficiency.

Smart decision-making: Through the analysis and mining of massive data, combined with the logical relationship model, the effective information is extracted, which provides effective assistance for operation and maintenance decision-making and improves the management level.

Features

● Reliable monitoring of all aspects of pipe gallery information

Real-time comprehensive monitoring of urban engineering pipelines such as water, electricity, gas, heat, and communication;

Reliable perception and remote control of the operating status of electromechanical equipment;

The explosion-proof and intrinsically safe integrated equipment specially designed for gas tanks and rain and sewage tanks can realize uninterrupted real-time monitoring of explosive gases.

● Build a comprehensive security strategy

A multi-level security line of defense is composed of electronic manhole covers, infrared radiation, biological sensing, and video detection;

Realize all-weather anti-accidental intrusion prompts and real-time intrusion alarms.

● Fault warning based on big data analysis

Through big data mining technology, it can predict the trend of data and abnormal changes, and give early warning of possible failures.

● "One Picture" mode to display intuitively

Display all kinds of information of the pipe gallery in a unified way through the "one picture" mode;

Support 3D GIS, 360-degree visual display of the inside of the pipe gallery;

Combine virtual reality technology and remote control technology to realize autonomous roaming and remote control of equipment.

● An open system based on standard protocols

Support general interface protocol, which is convenient for system expansion or access to a higher-level system platform;

Support most mainstream communication protocols at home and abroad, which is convenient for system integration and expansion;

It adopts modular design and combines decentralized control with centralized control, which is suitable for monitoring needs of different scales and types.

● High reliability

Product design in line with industrial standards to ensure reliable operation in harsh environments;

A redundant communication network combining wired and wireless is supported to ensure communication reliability.

Components of Smart Pipe Gallery

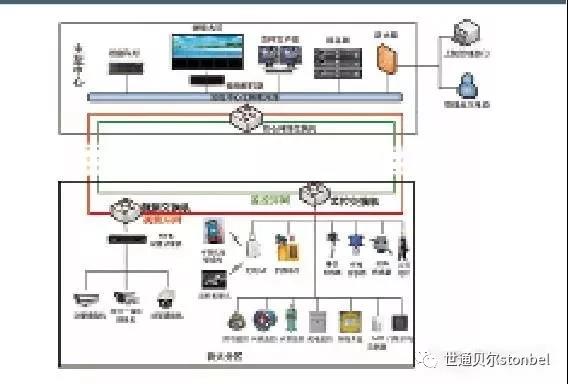

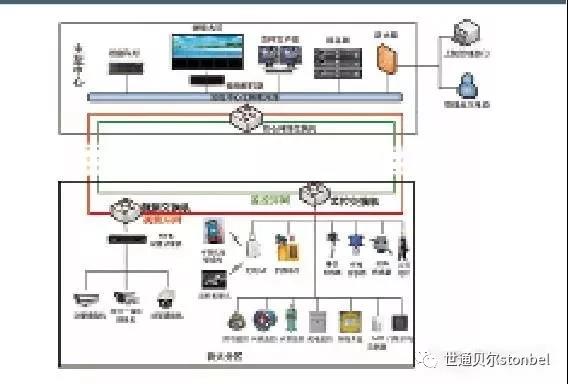

● System composition

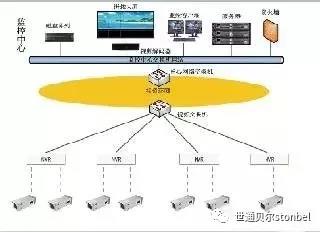

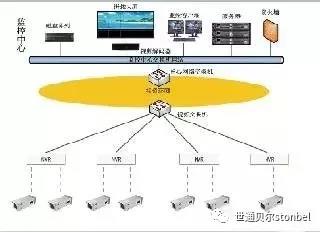

● Network Architecture

The double-loop structure is adopted to separate video data from monitoring data (such as on-site smart devices, smart meters, etc.), so that security and monitoring do not affect each other, ensuring the stable operation of the network.

Introduction to Subsystem - Security System

Video surveillance

By using a low-light high-definition network camera combined with a hard disk video recorder, functions such as real-time video monitoring, video query, and motion detection can be realized. .

Intrusion Detection

In the important nodes in the pipe gallery: personnel entrances and exits, feeding ports, vents, lead-out sections, etc., infrared microwave detectors and sound and light alarms are installed to monitor personnel entering and leaving, so as to realize unauthorized entry and alarm.

Smart manhole cover

The intelligent manhole cover is set at the escape port of the pipe gallery and the maintenance well, and the manhole cover is locked and unlocked by remote control, thereby preventing the entry of unauthorized personnel. At the same time, the manhole cover can feed back the working status to the monitoring center to realize the functions of intrusion alarm, anti-theft, and anti-disassembly.

Access Control System

The access control system can record and control the authority of personnel entering and exiting important areas of the pipe gallery, and can realize linkage control functions with video surveillance systems and fire alarm systems. When there is a fire alarm, the access control system will open the electric door lock of the fire area according to the pre-defined route, so that people can evacuate in time.

Visual tour

The visual inspection system uses smartphones as inspection instruments, and uploads inspection information to the server in real time through the WIFI wireless network to ensure that inspection personnel are in place. It can receive the task instructions issued by the monitoring center in real time, and generate inspection tasks in real time according to the instructions of the monitoring center, which can effectively improve the work efficiency of the inspection team and make the inspection work more visible.

Robot Inspection

With the intelligent orbital inspection robot as the core, it carries various environmental sensors, thermal imagers, cameras, robotic arms and other equipment, and transmits data to the monitoring platform in real time through the WIFI network to achieve 24-hour uninterrupted access to the pipe gallery environment and equipment. Monitoring, and can carry fire bombs, plugging agents to carry out fire-fighting and plugging tasks.

Introduction to Subsystem—Monitoring and Monitoring System

Environmental Monitoring

Real-time monitoring of various environmental parameters in the pipe gallery, and alarm prompts for abnormal information to ensure the safety of personnel and the normal operation of the pipe gallery.

Electrical equipment monitoring

Real-time online monitoring and control of electrical equipment such as ventilators, drainage pumps, lighting equipment, pipeline valves, power distribution cabinets, etc. in the pipe gallery, and data interaction with subsystems such as environmental monitoring systems, safety protection systems, and fire protection systems. Realize linkage and mutual control.

People monitoring

Through the card reader installed in the pipe gallery, real-time reading of the positioning and labeling card information carried by the personnel entering the corridor can realize the identification of the location, quantity and identity of the personnel entering the corridor, and can accurately identify the dynamic status of the personnel in the pipe gallery. The situation is reflected to the monitoring center, so that the management personnel can grasp the movement trajectory of the personnel in the pipe gallery at any time, so as to facilitate more reasonable scheduling management.

High Voltage Cable Monitoring

It is composed of functional modules such as distributed optical fiber temperature measurement (DTS), partial discharge monitoring, sheath circulation monitoring, etc. Through perfect condition monitoring, as well as analysis and evaluation of monitoring data, it provides preventive maintenance advice for high-voltage cables.

Structure and settlement monitoring system

The online monitoring system for the settlement of the pipe gallery monitors the settlement of the pipe gallery body by installing a differential pressure deformation sensor on the inner wall of the pipe gallery, and uses a crack meter to monitor the plane displacement of the jacking pipe and the standard section. Based on the obtained data, the system analyzes the over-limit indicators that affect the safety of the pipe gallery structure and gives an alarm in real time, so as to detect the disease in time and judge its safety status, so as to take timely measures to ensure the stability of the pipe gallery structure.

Communication system

By setting up fixed telephones, loudspeakers, wireless APs, intelligent mobile terminals and other equipment in the pipe gallery, wired and wireless real-time communication between inspection personnel and between inspection personnel and the monitoring center can be realized.